Iron Acetate

Making a batch of iron acetate wood stain from household materials.

"Natural" Stains

For me, much of the appeal of hand tool woodworking is getting up close and personal with the processes of crafting. I enjoy hand planes because of the feedback I can feel from the wood. This same perspective can be applied to finishing of wooden objects.

Iron Acetate Experiments

WARNING: this is a chemical reaction. Do not attempt science without proper safety precautions.

To make iron acetate at home, add steel to household vinegar and let it sit, uncovered. That's it.

NOTE: leaving the container uncovered is critical to permit gases to escape.

I tried a few different ways of making this in small containers (spice jars) before I found good results.

- Plane iron shavings: great results fast, but obtaining plane iron shavings is very tedious.

- Steel wool straight from the package, dropped into cold vinegar: poor results.

- Steel wool straight from the package, dropped into hot vinegar: poor results.

- Washed steel wool dropped into hot vinegar: great results, but slower than iron shavings.

In each of these cases, I'm judging the quality of results by how strong the resulting solutions were, and also taking into account how long it took to develop a strong solution.

What I learned is that steel wool fresh from the package is covered in a thin coating of something (oil perhaps) which prevents it from interacting with the vinegar. A pad of washed steel wool may dissolved completely after about a week. Meanwhile, unwashed steel wool did not dissolve entirely, even after 3 weeks.

Time-Lapse

I took these pictures in approximately the same lighting conditions to better show the color change over time. Occasionally I would shake the container to mix up the precipitated sediment at the bottom, and to distribute the floating rust-like flakes from the top.

Figure 1: Day 0, full of 0000-grade steel wool

Figure 2: Day 2, about half-dissolved

Figure 3: Day 4, completely dissolved (I shook the jar before taking the photo)

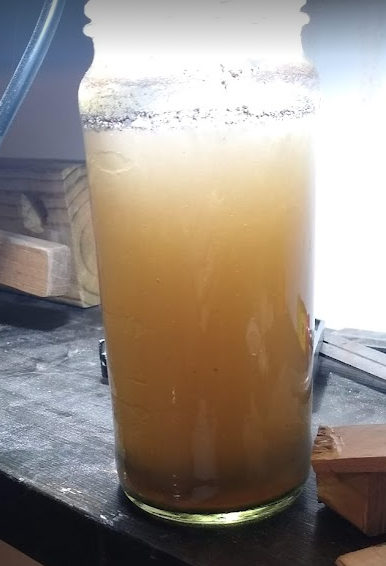

Figure 4: Day 9, a lovely color gradient

Figure 5: Day 15, more uniform red throughout

Figure 6: Day 24, more rusty sediment floating near the top

Figure 7: Day 39, diminishing returns

As you can see, the majority of the reaction is mostly done by day 9, and after about 3 weeks very little is happening. By this point, it should be strained through a filter to remove the sediment and then it will be ready to use.

Woods with higher tannin content react more strongly to iron acetate stain. I found a sample of oak to be especially reactive, turning dark purple. My samples of hard maple turned a pleasant weathered gray color. Pine turned a dull gray-green, and ash turned almost olive green.

As I do more woodworking projects, I plan to experiment with this stain and other finishing techniques.